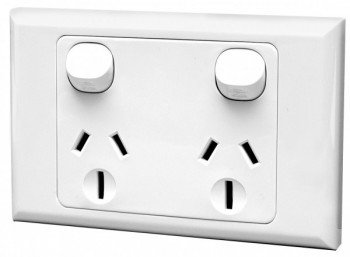

We are seeing more of these wall plates these days in the “slimline” design with removable cover plates as opposed to the older “thicker” designs. The standard requires that when mounted, and if the screw heads can be touched with the “standard test finger”, then there shall be an insulating cover over the screw head to prevent the end user from touching it in service.

Often an un-earthed metal bracket or mounting box is used in the wall cavity and if this ever becomes live then the screw heads will become live to touch as well. The only protection is to have plastic plugs inserted over the screw heads. You might think that because you have a cover plate that clips over the installed switch plate then you are ok, but the standard requires the test to be performed after the cover plate has been removed – whether you need a tool to remove it or not. The types of plates being referred to are those that are interchangeable, for decoration or removable for “painting and decorating”. If you can touch the screw heads in your wall plates then you will need to have plastic plugs supplied that effectively insulate the screw heads and you will need to have marking information regarding the fitting of these plugs in the field.